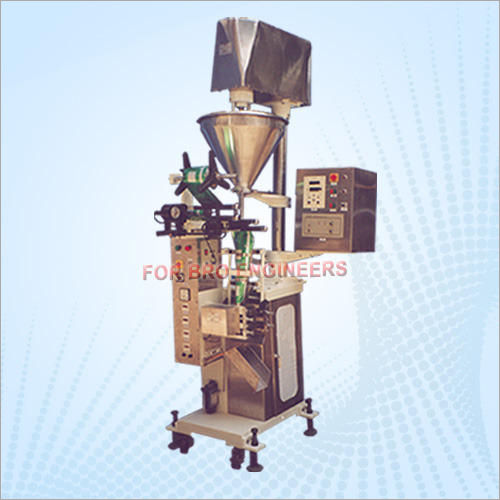

Granules and Pulses Sachet Packer Machine

Price 175000.00 INR/ Piece

Granules and Pulses Sachet Packer Machine Specification

- Type

- Sachet Packing Machine

- Material

- SS 304 MS powder coated

- Feature

- Heavy Duty Machine, Durable

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- 0-1 Horsepower (HP)

- Warranty

- 01 year

Granules and Pulses Sachet Packer Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 4 Week

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, South America, Asia, Western Europe, Central America, North America, Africa

- Main Domestic Market

- All India

About Granules and Pulses Sachet Packer Machine

Sachet Packer Machine - Granules, Pulses and Detergent

Sachet packing machines offer packing solutions for powders, granular products, liquids and pastes mainly in small size unit packs. Varity of dozing heads available makes these machines capable of handling various products with different physical properties. Machines packs product in to 3 or 4 side sealed pillow pouches formed from printed laminate roll . Photoelectric registration helps in precise print positioning on the pouch is provided.

Suitable for

- Wholse Spices, Granular Chemicals, Sauf/Dhanadal , Mukhwas, pulses, Grains, Detergent, Salt, Pepper etc,

Other Dozing Units

- Auger Filler: With Photoelectric sensor controls for dozing of non-free flowing/fluffy powders

- Volumetric Cup Filler: With/Without volume adjustment for free flowing powders

- Liquid Dozer: Piston pump with micro adjustment of volume

- Paste Filler: For dozing of thick viscous liquids with pump and pressure screw if required

Salient Features:

- Easy changeover of pack size and output control.

- GMP and Standard models.

- Robust construction with user friendly controls.

- Photoelectric registration for precise print positioning.

- Contact parts made from S.S.304 (S.S.316 contact parts on request)

Technical Specifcations

| Item | Parameters | Specifications |

| Operational specifcations | Capacity | From 10gm 50gms free flow grannules |

| Control | Electromechanical with photoelectric sensor. | |

| Operation mode | Automatic | |

| Packing speed | Upto 30 pouches per minute with single tracks depending upon the product density and packsize. | |

| Pouch formation | With liner former with max size upto 220mm width of laminate. | |

| Pouch type | 3/ 4 side sealed pouch. | |

| Max pouch size | 100mm x 150mm max. | |

| Vertical seals | Roll pulling and vertical seales with die rollers through epicyclic gear train. | |

| Horizontal seals | With rotary cross seal rollers with eccentric for matching of linear speed of pouch movement. | |

| Heaters | Cartridge heaters 250w x 4nos. | |

| Dozer | Volumetric cup filler for grannular products with height adjustmen and provided with components suitable for one paksizes. | |

| Filling accuracy | + 2% at constant powder level in the machine hopper and consistancy of bulk density | |

| Product feeding | To be arranged by you (can be supplied optionally) | |

| Machine hopper | 10 litres. | |

| Control panel | Moc | Inbuilt with the machine. M.s.body |

| Controller | Solid state electronic controller with photoelectric sensor for print mark registration. | |

| Temperature controllers | Digital time proportional temperature controllers with j type thermocouples. | |

| Drive | Motors | 0. 5 h.p. Single phase . For main machine (variable speed drive optional) |

| Gear box | Worm reduction gear box | |

| Physical specificaions | Moc | All parts coming in direct contact of the product made from s.s. 304. All other parts made from MS/CI ( for GMP models all parts are made from s.s.304 / covered with ss304 sheets/ ENP coated. ) |

| Main machine | 900mm x1000mm x 1800mm | |

| Net weight | 550kgs approx. | |

| Mobility | Provided with castor wheels.. |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sachet Packing Machine Category

FFS Sachet Packer Machine

Price 540000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Automatic Grade : Automatic

Material : Mild steel, Stainless steel

Type : FFS Sachet Packer Machine, Other

Sachet Packing Machine

Price 175000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Automatic Grade : Automatic

Material : SS 304 MS powder coated

Type : Sachet Packing Machine, Other

Servo Powder Filling Machine

Price 540000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Automatic Grade : Automatic

Material : Mild steel, Stainless steel

Type : Servo Powder Filling Machine, Other

Liquid Sachet Packer Machine

Price 178000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Automatic Grade : Automatic

Material : Mild steel, Stainless steel

Type : Liquid Sachet Packer Machine , Other

|

FOR-BRO ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS