Volumetric Cup Filler

Price 1450000 INR/ Piece

Volumetric Cup Filler Specification

- Application

- Food, Chemical, Pharmaceutical Industries

- Noise Level

- 70 dB

- Usage

- Granule, Powder, and Small Solid Filling

- Power Supply

- Single Phase

- Filling Range

- 10 to 1000 grams (adjustable cups)

- Type

- Volumetric Cup Filler

- Material

- Stainless Steel

- Feature

- High Accuracy Filling, Easy to clean

- Auxiliary Packaging Machine Type

- Automatic Granule Filling Machine

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control Panel

- Drive Type

- Electric Motor

- Power

- 1.5 kW

- Weight (kg)

- Approx. 350 kg

- Dimension (L*W*H)

- 1200 x 900 x 2000 mm

- Color

- Metallic Silver

- Sealing Type

- Heat Sealing Compatible

Volumetric Cup Filler Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 4 Week

About Volumetric Cup Filler

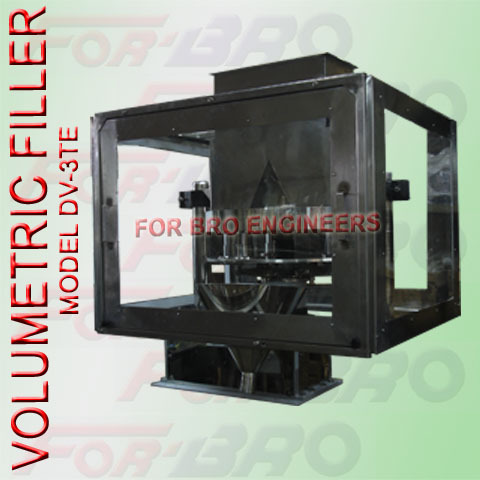

Volumetric Cup Filler - Dust Free Model

We offer a complete range of Volumetric Cup Fillers in standard and customizable models. Semi-automatic Volumetric cup fillers are designed for filling free flowing powders and grannuals. GMP models are available to suit international quality standards specically for pharma and Food industry. These machines can be delivered with dust free enclosure to ensure that the healthy environment is maintained. This is specifcally requried where material is hazareodus to the health of the people working in the premises.

Simple construction and easy maintenace makes these machines highly suitable for industry where skilled man power is a major hurdle.Correction of volume can be done without stopping the machines to adjust the batch to batch various of the product.

Suitable for

- Chemical and Detergent Industry, Salt, Detergent, Grains,Pulses.

Salient Features

- Volumetric filler with dust free enclosure.

- Ideal for International Standard /Touch free environment

- Recommended for Hazardous materials

- Capacity to handle wide range of products and pack sizes.

- Correction of Volume can be done without stopping the machine.

- Easy changeover of product and pack sizes.

- Contact parts made from S.S.304( S.S.316 contact parts on request).

- Sturdy, simple construction assists maintenance and cleanliness.

-Jumbo models available for handling large volume of powders.

Technical Specifcations

| Item | Parameters | Specifications |

| Operational specifcations | Capacity | Free flow granular powder from 150 cc to 1500 cc |

| Filling cups | Telescoping filling cups for one pack-size (1000gms free flow salt) will be provided with the machine | |

| Volume control | Telescopic cups with adjustable volume for compensation of variation in bulk density | |

| Volume cont. Mechanism | With helical gearing fiber hand wheel and ss spindle | |

| No. Of heads | Two | |

| Operation mode | Manual with two operators for two heads | |

| Filling speed | 40 discharges per minute ( 17 discharges per minute on each side) | |

| Filling accuracy | + 2% at constant powder level in the machine hopper and consistency of bulk density | |

| Powder feeding | To be arranged by you. | |

| Drive | Motor | 0.75 hp motor |

| Gear box | Special heli-worm reduction gear box enclosure for helical gears | |

| Physical Specifications | Machine hopper | 50 litres. With adjustable inclined baffle |

| Dozer disc | 10mm thick machined ground dozer discs. | |

| Machine body | With heavy cast iron frames and top plat made from ss304.guards made from ss304 | |

| Discharge hopper | Discharge hopper with outlet diameter to suit the pouch mouth | |

| Moc | All parts coming in direct contact of the product made from s.s. 304. All other parts made MS/CI powder coated / painted. | |

| Mounting | Suitable for table top mounting. Optional supporting frame available. | |

| Overall dimensions | Main machine | 1100mm x 850mm x 1300mm |

| Supporting frame(optional) | 650mm x 400mm x 900mm | |

| Net weight | 300kgs approx |

Precision and Versatility for Granular Products

Designed with high accuracy in mind, this volumetric cup filler handles a wide range of filling needsfrom powders to small solid granulesacross food, chemical, and pharmaceutical sectors. Its stainless-steel build and PLC-controlled system ensure lasting performance with consistent, error-free filling.

Adaptable Filling and Easy Maintenance

With adjustable cups, the machine accommodates various gram weights between 10 and 1000 grams, ideal for flexible packaging requirements. Its sleek, metallic silver body is simple to clean, contributing to hygiene and operational efficiency in demanding environments.

FAQs of Volumetric Cup Filler:

Q: How does the volumetric cup filler achieve precise filling accuracy?

A: The volumetric cup filler utilizes adjustable measuring cups controlled by a PLC system, ensuring each fill matches the set weight range (101000 grams). Stainless-steel cups and an electric motor drive provide uniform dispensing for granular, powder, and small solid materials.Q: What industries commonly use this automatic granule filling machine?

A: This machine is widely utilized in the food, chemical, and pharmaceutical industries, where precise, hygienic, and efficient granule or powder filling is essential for packaged products.Q: When should I use a volumetric cup filler instead of other filling machines?

A: The volumetric cup filler is ideal when you need high-speed, batch filling of free-flowing granules or powders, accuracy within a set weight range, and easy changeover between product sizes without extensive recalibration.Q: Where can this machine be installed and operated efficiently?

A: Thanks to its compact footprint and single-phase power requirement, the volumetric cup filler can be installed in a variety of factory settings, particularly where space is limited or frequent cleaning is necessary.Q: What is the process for adjusting the filling volume on this machine?

A: To adjust the filling volume, operators simply recalibrate the measuring cups through the PLC control panel, enabling flexible and repeatable batch sizes ranging from 10 to 1000 grams without interrupting the packaging process.Q: How does the easy-to-clean design benefit daily operations?

A: Its stainless-steel construction and streamlined components allow for quick, thorough cleaning, minimizing downtime and ensuring compliance with hygiene standards in sensitive production environments.Q: What are the operational benefits of the PLC control and electric drive system?

A: The combination of PLC control and electric motor drive delivers precise, automated operation with low maintenance, stable power consumption (1.5 kW), and consistent performance at noise levels 70 dB.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Volumetric Cup Filler Category

Volumetric Cup Fillers

Price 162000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Volumetric Cup Filler , Other

Warranty : 01 year

Automatic Grade : Automatic

Control System : PLC Control

Volumetric Cup Filler Machine

Price 145000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Volumetric Cup Filler Machine, Other

Warranty : 01 year

Automatic Grade : Automatic

Control System : PLC Control

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS