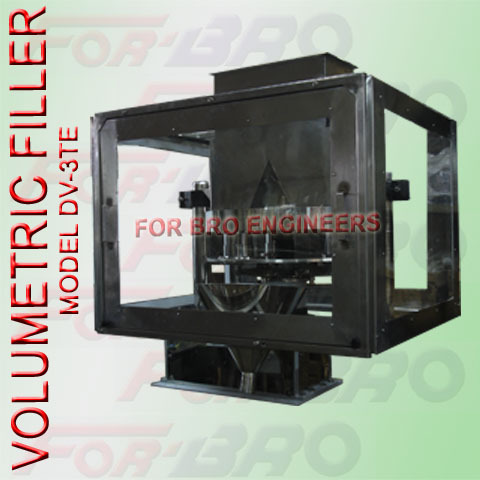

Volumetric Cup Fillers

Price 162000.00 INR/ Piece

Volumetric Cup Fillers Specification

- Type

- Volumetric Cup Filler

- Material

- Mild steel, Stainless steel

- Feature

- Heavy Duty Machine, Durable

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- 0.5 TO 01 Horsepower (HP)

- Warranty

- 01 year

Volumetric Cup Fillers Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 4 Week

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Asia, Western Europe, Central America, Africa

- Main Domestic Market

- All India

About Volumetric Cup Fillers

Owing to our expertise in this field, we are engaged in offering our clients a broad assortment of Volumetric Cup Fillers that are suitable for filling free flowing powders and granules. These fillers are used for filling detergent, chemicals, spices, pulses etc. in pharmaceutical, chemical and food industry. The offered fillers are manufactured by utilizing high grade raw material and cutting-edge technology under the guidance of experienced professionals. Owing to their to rugged construction and durability, these Volumetric Cup Fillers are highly appreciated in the industry.

Features:

-

Excellent functionality

-

Hassle free performance

-

Energy efficiency

-

Easy to operate

Other information:

One of the pioneer in the packaging industry, For-bro offers offer a complete range of Volumetric Cup Fillers in standard and customizable models. For-Bro introduced double discharge mechanism in Indian salt industry and revolutionized the salt packing industry with very high speed low maintenance packaging where sophisticated machines failed to survive due to corrosive environment.

Semi-automatic Volumetric cup fillers model DV-3T are designed for filling free flowing powders and grannuals. Machines are used for filling detergent, chemicals, Whole spices, Pulses etc.Simple construction and easy maintenance makes these machines highly suitable for industry where skilled man power is a major hurdle.

GMP models are available to suit international quality standards specially for pharma and Food industry. These machines can be delivered with dust free enclosure. Correction of volume can be done without stopping the machines to adjust the batch to batch various of the product.

Suitable for

-

Grains, Pulses, Wholse spices, Salt, Detergent etc

Salient Features:

-

Volumetric filler with dust free enclosure.

-

Capacity to handle wide range of products and pack sizes.

-

Correction of Volume can be done without stopping the machine.

-

Easy changeover of product and pack sizes.

-

Contact parts made from S.S.304 (S.S.316 contact parts on request).

-

Sturdy, simple construction assists maintenance and cleanliness.

-

Completely mechanical machine.

-

Jumbo models available for handling large volume of powders.

-

First Ever concept in volumetric cup fillers

Technical Specifications:

| Item | Parameters | Specifications |

| Operational specifications | Capacity | Free flow granular powder from 150 cc to 1500 cc |

| Filling cups | Telescopic filling cups for one pack-size will be provided with the machine | |

| Volume control | Telescopic cups with adjustable volume for compensation of variation in bulk density | |

| No. Of heads | Two | |

| Operation mode | Manual with two operators for two heads | |

| Filling speed | 34 discharges per minute (17 discharges per minute on each side) | |

| Filling accuracy | + 2% at constant powder level in the machine hopper and consistency of bulk density | |

| Powder feeding | To be arranged by you. | |

| Drive | Motor | 0.75 hp motor |

| Gear box | Worm reduction gear box . | |

| Transmission | Through helical gearing. | |

| Physical specifications | Machine hopper | 60 litres. |

| Dozer discs | 5mmthick direct or 10mm thick machined ground dozer discs. | |

| Machine body | With heavy cast iron frames and top plate made from ss304. Guards made from ss304 | |

| Discharge hopper | Discharge hopper with outlet diameter to suit the pouch mouth | |

| Moc | All parts coming in direct contact of the product made from s.s. 304. All other parts made M.S/CIpowder coated / painted. | |

| Mounting | Suitable for table top mounting. Optional supporting frame available. | |

| Overall dimensions | Main machine | 1100 mm x 850 mm x 1300 mm |

| Supporting frame (optional) | 650 mm x 400 mm x 900 mm | |

| Net weight | 300 kgs approx |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Volumetric Cup Filler Category

Volumetric Cup Filler

Price 1450000 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Other, High Accuracy Filling, Easy to clean

Drive Type : Other, Electric Motor

Automatic Grade : Automatic

Control System : Other, PLC Control Panel

Volumetric Cup Filler Machine

Price 145000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Heavy Duty Machine, Durable

Drive Type : Electric

Automatic Grade : Automatic

Control System : PLC Control

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS